Vespel, a high-performance polyimide material, has gained recognition as a pioneering material in the realm of plastics.

Known for its exceptional properties and diverse applications, Vespel stands as a testament to innovation and engineering excellence.

In this article, we delve into the composition of Vespel and explore its wide range of applications across various industries.

Vespel, a high-performance polyimide material, has gained significant recognition across various industries due to its exceptional properties and versatility.

Its unique combination of mechanical strength, thermal stability, chemical resistance, and low friction coefficient has led to its extensive utilization in numerous critical applications.

Post Contents

Composition And Properties

Vespel is a polyimide material that comprises of polymer chains with imide functional groups.

It is created through a complex synthesis process involving the reaction of dianhydrides and diamines.

The resulting material exhibits remarkable properties that set it apart from conventional plastics.

Vespel is known for its high temperature resistance, excellent mechanical strength, low friction coefficient, and chemical inertness.

Aerospace Applications

Vespel has found extensive use in the aerospace industry, thanks to its exceptional performance properties.

It is utilized in various applications, including aircraft engine components, bearings, seals, wear rings, and bushings.

Its ability to withstand high temperatures, low wear, and low friction make it an ideal material for critical aerospace parts, contributing to enhanced performance, reliability, and safety.

Vespel plays a crucial role in aerospace applications, where high-performance materials are essential.

It is commonly used in aircraft components such as bushings, bearings, seals, and thrust washers.

Vespel’s exceptional wear resistance, high-temperature stability, and low coefficient of thermal expansion make it ideal for maintaining performance in demanding aerospace environments.

Automotive Industry

In the automotive sector, vespel has emerged as a valuable material for different applications.

It is commonly used in components such as thrust washers, bushings, and bearings, where high temperature resistance, low friction, and durability are essential.

Vespel’s excellent mechanical properties and self-lubricating characteristics reduce friction and wear, contributing to improved fuel efficiency, reduced emissions, and extended component lifespan.

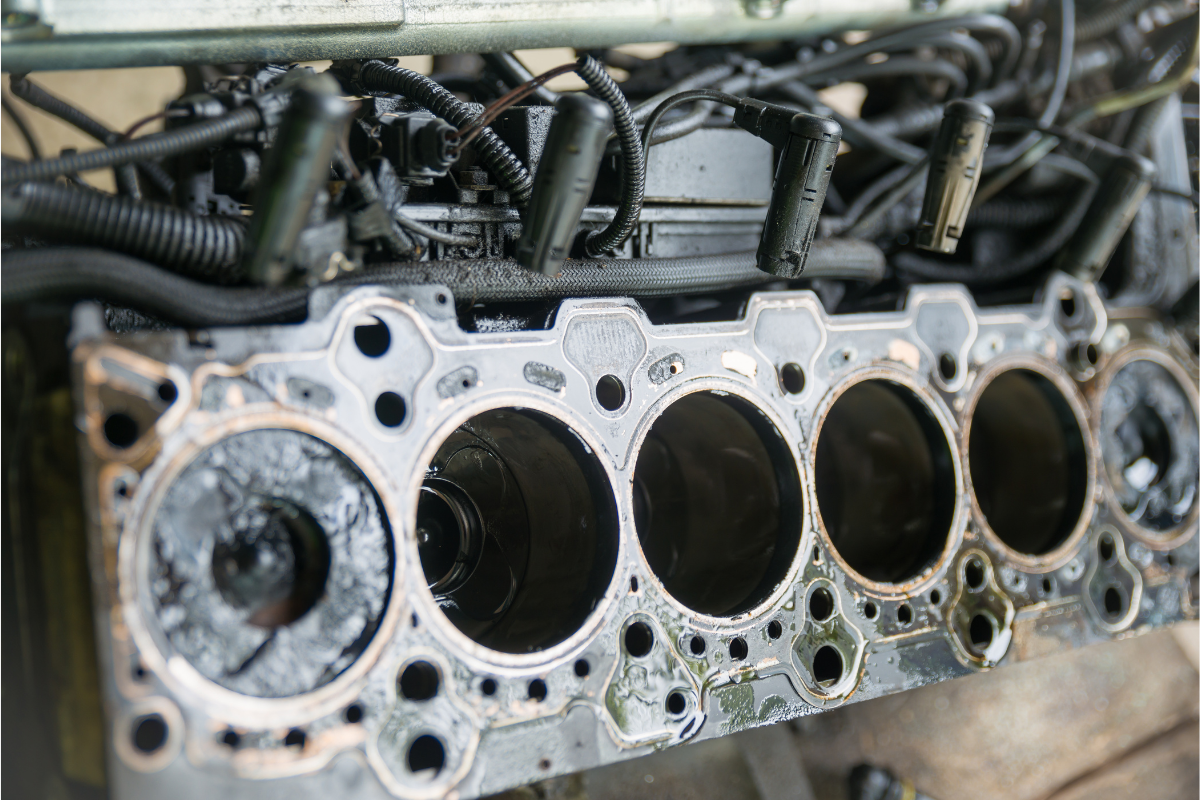

In the automotive industry, Vespel finds application in components such as thrust washers, piston rings, and valve seats.

Its ability to withstand high temperatures, excellent dimensional stability, and low friction characteristics contribute to improved engine efficiency and durability.

Additionally, Vespel’s resistance to chemicals and lubricants further enhances its suitability for automotive applications.

Industrial and Manufacturing

Vespel plays a significant role in industrial and manufacturing processes due to its unique properties.

It is used in various equipment and machinery applications that require high temperature resistance, chemical inertness, and low friction.

Examples include pump wear rings, compressor components, gaskets, electrical insulators, and valve seats.

Vespel’s ability to maintain dimensional stability and perform in demanding environments enhances productivity, reduces maintenance, and extends equipment life.

Semiconductor and Electronics

In the semiconductor and electronics industries, Vespel finds applications in critical parts such as wafer handling, test sockets, and pick-and-place tooling.

Its high purity, dimensional stability, and low outgassing characteristics make it suitable for cleanroom environments.

Vespel’s electrical insulation properties and resistance to thermal stress contribute to the reliability and precision required in semiconductor manufacturing processes.

Vespel is extensively used in the semiconductor industry, particularly in wafer-handling applications.

Its excellent dimensional stability, low outgassing properties, and high-purity characteristics make it an ideal material for use in critical environments such as cleanrooms.

Vespel’s non-contaminating nature and ability to withstand high-temperature processes ensure the integrity of semiconductor manufacturing processes.

Energy and Oil & Gas

Vespel is utilized in the energy and oil & gas sectors for demanding applications. It is employed in equipment such as bearings, seals, valve seats, and electrical connectors.

Vespel’s ability to withstand extreme temperatures, resist chemicals, and maintain dimensional stability makes it suitable for harsh operating conditions.

It contributes to increased efficiency, reduced downtime, and enhanced safety in power generation, petrochemical, and oil exploration applications.

Medical and Healthcare

In the medical and healthcare fields, Vespel finds application in various devices and equipment.

Its biocompatibility, chemical inertness, and excellent dimensional stability make it suitable for components such as medical connectors, surgical instruments, implants, and diagnostic tools.

Vespel’s ability to withstand sterilization processes and resist chemicals ensures the integrity and reliability of medical devices.

Conclusion

Vespel stands as a remarkable material that has revolutionized the landscape of plastics with its exceptional properties and versatility.

Its composition and synthesis process yield a polyimide material with high temperature resistance, excellent mechanical strength, low friction coefficient, and chemical inertness.

The wide range of applications across industries such as aerospace, automotive, industrial, semiconductor, energy, and healthcare highlight the significance and adaptability of Vespel.

As research and development in materials science continue to advance, Vespel remains at the forefront of innovation, offering enhanced performance, durability, and reliability in critical applications.