The process of inkjet printing originated in the mid-twentieth century as a newer type of printing that recreates text or images by propelling microscopic droplets of printer ink onto a medium such as paper, plastic, or some other writing surface.

Inkjet technology originated in 1833 when Felix Savant of France discovered that liquid drops, when delivered through a narrow opening, would remain uniform in size. In 1878, the English scientist John William Strutt (Lord Rayleigh), published a description of the process mathematically and later went on to win the 1904 Nobel Prize in Physics.

In 1948, Swedish physician Rune Elmqvist developed the first inkjet printer, which he called the “mingograph” while working at the German company Elema-Schönander, which later became Siemens.

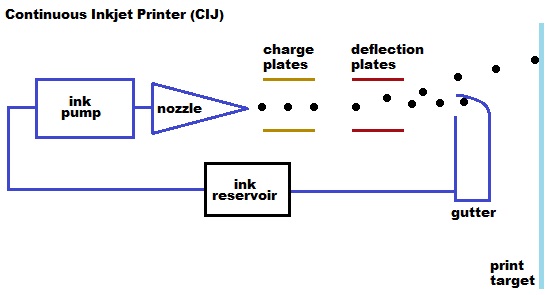

In the early 1960’s, Dr. Richard Sweet of Stanford University demonstrated that when an ink stream was broken down into droplets of uniform spacing and size, an electric charge could be applied to the droplets to produce a continuous ink stream. As the charged droplets were passed through the electric field, he discovered they could be deflected onto the substrate and create an image. The process became known as continuous inkjet printing (CIJ).

By the late 1960’s, Dr. Sweet’s invention led to the introduction of several inkjet products including the Mead DIJIT and A. B. Dick VideoJet. In the 1970s, IBM licensed the technology and created the IBM 4640 printer in 1976 as a “hard carrier peripheral text printing device”.

In 1972, Physics Professor Dr. Hellmuth Hertz of Lund University in Sweden independently developed a number of continuous inkjet printing methods including the technology to produce color images that were of a quality equal to color photographs.

The CIJ method of printing is used commercially for marking and coding numerous products and packages in industries such as food, beverage, construction, cosmetics, pharmaceutical, automotive, electronics, and other industrial sectors. CIJ printers work on a simple design and are reliable solutions because they are able to mark or code on almost any surface at any speed or orientation, and with multiple characteristics such as shape, size, and texture. CIJ printers can print date and lot codes, barcodes, logos, and text onto a variety of substrates such as paper, glass, metal, plastic, wood and more.

The major advantages of CIJ are that it produces ink droplets that travel at a very high velocity. This allows the print head to be positioned at a relatively long distance from the substrate for very high speed printing. A second advantage is that since the jet is always in use, nozzle clogging is rare, therefore allowing such volatile solvents as ketones and alcohols to also be employed which gives the ink the ability to adhere better to the medium and dry quickly.

CIJ printers are capable of running for many hours before they require service and they also work well in high-pressure environments. The process has proven to be reliable and cost-effective, providing an ideal printing solution for fast-moving production lines, making it the standard of today’s commercial inkjet technology.