Warehouse safety has come a long way since the chaos of the 20th century — and even more if we slip back in time to the outset of the Industrial Revolutions.

Today, according to the U.S. Bureau of Labor Statistics, there are less than 30 fatalities per year in warehouses.

Warehouse safety metrics and standards reveal that 4.8 for every 100 full-time workers are injured in warehouse accidents and the majority of injuries are small and easily managed.

Nevertheless, accidents keep occurring, and some of them are incredibly easy to prevent. Improving your warehouse safety should be your manager’s number one priority.

Creating a culture that values your employee’s safety guarantees that you run a smooth, efficient, competitive, and stable warehouse.

In this article, we’re going to give you tips on how to improve your warehouse safety stats’.

Post Contents

What is Warehouse Safety?

Warehouse safety is a set of guidelines and industry practices that help warehouses and distribution centers ensure a safe working environment for their personnel.

It’s one of the most important factors when it comes to running a warehouse.

What’s critical to understand about warehouse safety is that you have to approach it actively and constantly, you simply can’t react to a situation, nor can you establish rules and then not oversee them or update them.

By taking a proactive stance on safety procedures, companies can prevent illness, injuries and promote a safe and healthy workplace.

They can also prevent lawsuits and total disruptions to their operations.

OSHA Warehouse Safety Rules

The Occupational Safety and Health Administration is continually taking a stance against shoddy workplaces — including does that disregard Health Acts and common Federally mandated guidelines.

It’s important to understand that aside from the unique work environment you have created, you have to follow 8 specific rules dictated by this organization.

The OSHA warehouse safety rules:

The general guideline that OSHA offers most organizations are:

- Make sure your warehouse is well ventilated.

- Implement proper lockout/shut-off procedures.

- Block off exposed or open areas — spaces where an employee could fall more than 4 feet.

- Clear floors, aisles, and surfaces of any hazards.

- Train employees on work safety procedures and the equipment they are going to use.

- Teach your staff proper ergonomics — one of the most common injuries in a warehouse comes from improper back lifts.

- Make sure all your employees, especially those that perform physical tasks, take periodic rests.

- Consider proper work practices when it’s time to determine how long it should take an employee to complete a task.

Shocking Warehouse Safety Metrics and Stats

Here are some stats’ to take into account when considering how to approach the subject of warehouse safety.

- Most injuries occur in docks, conveyors, and forklifts.

- More than 20,000 workers a year, over 25% of warehouse accidents, are because of forklifts. 90 people are killed, per year, by them.

- Another common safety issue is pallets — either overloaded pallets, or pallets that have been damaged during transportation, or pallets that need to be replaced. Not taking care of your pallets will result in injuries according to OSHA investigations.

- Aside from lawsuits, and insurance payments, OSHA can fine a company $7,000 for a minor infraction to $70K for a repeated offense or a major breach.

Warehouse Safety Ideas and Solutions

Along with general safety guidelines, OSHA has also created a list – and easy to follow one at that – on how to improve the most sections of your operations and how to bulk up for safety procedures.

Forklifts

25% of accidents are on account of manhandling forklifts — over 90 deaths nationwide per year.

It’s important to train and constantly certify forklift operators. It’s critical to establish safe operating procedures.

Hazard Communication

It’s important to teach your employees about the product they are handling and what their risk levels are.

This includes hazardous materials, toxic chemicals, and other goods that may in fact injure your staff.

Electric Wiring Methods

Another key element you need to integrate into your infrastructure is ground fault circuit interrupters. Over 19% of injuries occur on account of faulty wiring.

Fall Hazards

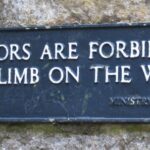

Install “fall restraint” systems, like railing and guardrails. It’s also pivotal that you set-up safety nets, and warning signs when needed.

Conveyors

Workers can be injured by conveyors, either by products running through them or due to receptive motions and awkward positioning.

Develop ways of locking out conveyors and train employees properly in their use.

Pallets

Buy and store pallets properly. Pallets that fit the right racks and that are in good condition.

One of the most common problems when it comes to warehouse safety procedures is that pallets become overused or badly employed.

They break apart and not only injure your employee but can damage the product they were carrying.

Manual lifting and Handling

Provide general ergonomic training and teach good lifting techniques — back pains are one of the most common warehouse injuries.

Rack Safety

Choose proper racks and maintain your racks and ground them with counterweights.

Racks are constantly being battered, mostly by vehicles and forklifts, this builds over time and can damage them and create load problems.

The Most Important Warehouse Safety Tip

Supervision and having an active role in warehouse safety is the most important tip we can give you.

Yes, you can adopt new trends and tech to automate your warehouse, like having robots and other services take the brunt of most of the jobs and the risk involved.

Yes, you can implement guidelines and teach your employees.

Nevertheless, unless you take an active stance on warehouse safety solutions and have an eagle eye on your whole operation and how your employees interact with one another, then you’re liable – sooner, rather than later – to become one more number on OSHA’s annual statistics report.