Computer aided design, more commonly known as CAD, has been around for over half a century, and has continued to evolve significantly in this time, influencing all sorts of industries in the process.

Today, CAD software is more accessible than ever, and it can even be implemented by amateur tinkerers who want to create a manufacturing setup in their own homes.

To appreciate just how significant CAD is to the modern world, let’s look at some of the main uses of this type of software, and what you can do to embrace it domestically, whether just for fun or with a view to starting your own business.

Post Contents

Providing Instructions To CNC Machines

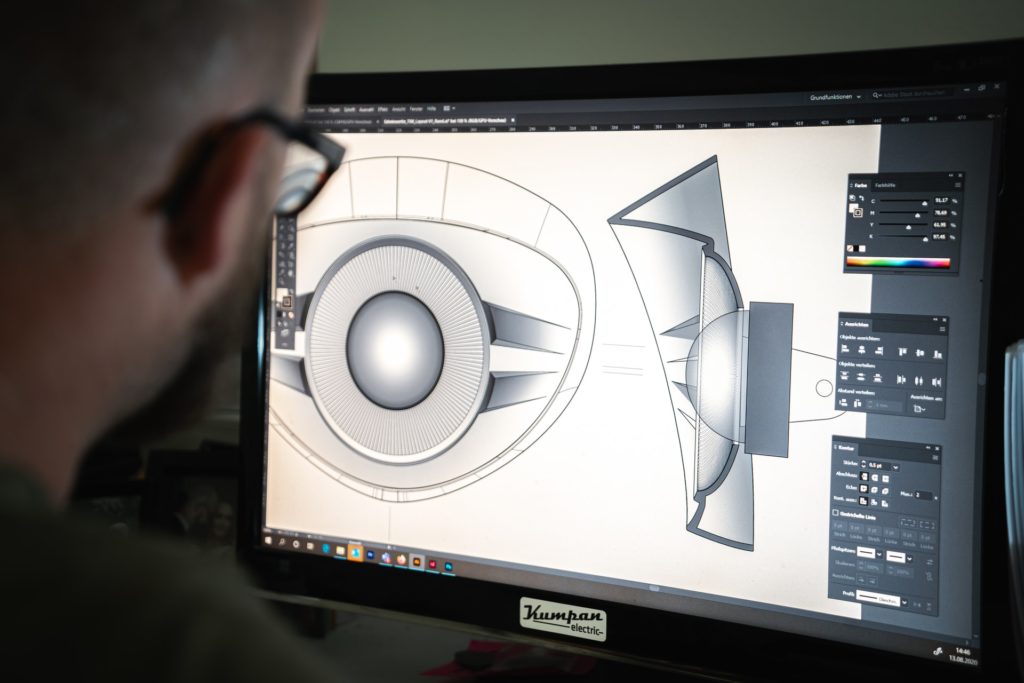

Most people will be familiar with CAD as it applies to the sister process of CAM (computer aided manufacturing). With a design for a component put together in CAD software, this can act as the blueprint for the operation of CNC (computer numerical control) machinery.

CNC gear comes in all shapes and sizes, and can handle lots of different duties with varied materials, from metal roll formers for working with sheet metals, to laser-based equipment which can cut, engrave and even clean. But how can you hope to afford this type of equipment for a home setup?

Purchasing A Used Metal Roll Former

The good news for enthusiasts and entrepreneurs is that because you can buy a used metal roll forming machine, or indeed any type of CNC equipment, via reputable online marketplaces, the cost of acquisition can be kept to a minimum.

Check over things like the number of hours of use that the unit in question has undergone, and look into the maintenance history as well, to ensure you can pick up second hand machines that will stand the test of time.

Because CNC is a broadly standardized code set, and because it is widely used in manufacturing, it is also almost universally compatible with CAD solutions, so that’s another reason to choose this type of gear for small scale production runs as well as prototyping.

Creating 3D Models For Construction Projects

Another of the important applications of CAD is as a means to help visualize projects which have yet to be put into action. This is particularly useful in a construction context, as it means that simple three dimensional models can be mocked up quickly, to act as a proof of concept for new developments which are in the earliest stages of coming to fruition.

While all of the largest building schemes in the world will have involved suitable CAD software at some stage, the scalability of this software means that it can also be harnessed by small businesses and home users as well. From mapping out how a space can be used, to designing new structures or extensions to existing buildings, CAD is an obvious option.

What is more, with the latest CAD tools being built with collaboration in mind, it is a breeze to share concepts with friends, family and colleagues, and also work together on a design so that everyone has the opportunity to give their input in a unified interface.

Enabling A New Age Of Additive Manufacturing

In recent years, additive manufacturing has been a disruptive force across the industry, and is proving particularly useful for people who want to design products and even manufacture items on a small scale from their own homes.

Also known as 3D printing, this is a process that is innately tied into the technologies and principles of CAD.

What makes additive manufacturing and CAD such close compatriots is that the former is able to unlock the full potential of the latter.

Simply put, 3D printing setups can be used to produce designs which were not possible to achieve using traditional, subtractive manufacturing techniques. This means that even the wildest, most innovative ideas of designers don’t have to remain trapped in a CAD file, but can be realized thanks to additive manufacturing machinery.

Boosting Productivity

Wherever and whenever CAD software is put into use, it has a positive impact on productivity, whether for an individual or an entire organization.

By stripping out the limitations of manual design methods and accelerating lynchpin processes, it is easier to turn an idea into a workable 3D render, and from here to get busy with the actual manufacturing.

Because of CAD, the future for small scale manufacturing is bright; you just need to procure the right equipment, the best software, and you’ll be good to go.