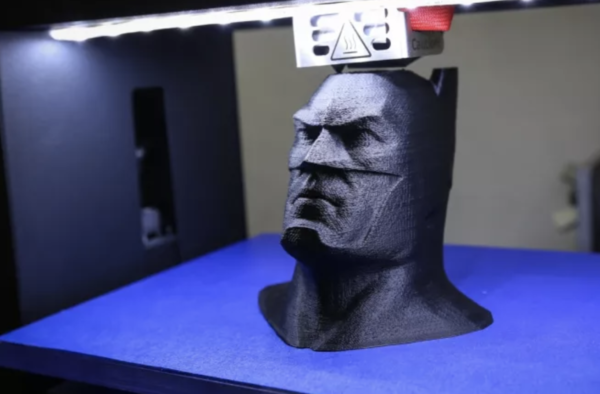

Since the advent of 3D printing machines, printing complex designs has never been easier.

As such, most people presume that producing 3D prototypes is a straightforward task. On the contrary, it’s imperative to note that mistakes are common in this trade and can happen at any time. As such, apart from the technical skills required, it is also important to understand the different dynamics that can bring about a problem or any unwanted results.

Understanding such mistakes and having the necessary knowledge on how to avoid them can save a lot of energy, time, and resources. Lack of such understanding can lead to unsatisfactory outcomes such as geometric inaccuracies, missing faces, and poor resolution among others.

This article seeks to enlighten you on how to avoid such errors by highlighting some of the most common mistakes in 3D printing and how to avoid them.

Post Contents

Applying the wrong technology

There are different technologies applied in 3D printing.

The technology to be used is basically determined on the basis of materials used. Whereas some materials can be printed together, such as Polyamide, Alumide, and ABS, others cannot and call for the use of varying technologies. Certain materials such as plastic require selective laser sintering or fused deposition modeling technology to attain the desired results.

Similarly, digital light processing and multijet printers are best suited for wax and resin materials. Therefore, to avoid using the wrong technology, take into consideration the materials you are using and ensure that your 3D printer uses the technology that best suits your materials.

Not setting up the machine properly

The most obvious reason why you might encounter errors or mistakes in your 3D printing is the mere fact that your machine is not properly set up. Therefore, it is important to have the technical knowledge required to set up the machine and detect any mishaps arising from a bad set up. Some of the common set-up blunders that cause errors in your printing include clogged print heads, out of filament and nozzles not working among others.

To avoid making such mistakes, it is important to have your machine set up properly by a person with the technical know-how. Also, take the time to carefully read and understand the instructions on the manual to help you set up the machine as required.

Not taking into account the file resolution

Picking the wrong resolution is a common mistake that most people make when printing 3D prototypes. The resulting prints tend to be uneven if the resolutions are too low or quite difficult to handle with if the resolution is too high. The only way you can rest assured that your prints will be top quality is by picking the right resolution.

Considering that standard triangle language (STL) is the most used file format when printing 3D designs, it is paramount that you choose the appropriate resolution for the file. Working with STL files is not easy because they only outline the outer surface of the prototype. An error in the STL format can bring about other problems including over-refined mesh, awful boundary edges, non-manifold edges, and intersecting faces.

Ignoring the wall thickness

The thickness of your surface is another important factor that people often overlook and tends to be another common cause for errors in your 3D model. If the walls of the surface are too thick, the model will be affected adversely as a result of inner pressure caused.

On the other hand, if the walls are too thin, the item can easily crack or break because some parts of the model cannot be printed. As such, to avoid making this mistake, it is imperative that you take the wall thickness into account before-hand.