Envision this: You’re in an industrial environment, which means you’re constantly exposed to potentially harmful chemicals and fumes and large, noisy machines.

You get a whiff of an unfamiliar aroma and immediately try to pinpoint its source. You suddenly feel lightheaded and bewildered.

I’m curious as to your daily routine. Workers are often put in this position in factories where they are exposed to toxic fumes.

This is why gas detectors are so necessary; they may save a worker’s life in a variety of dangerous scenarios.

Here, we’ll take a high-level look at why and how gas detectors are used in industrial environments to keep employees safe.

Post Contents

Applications Of Gas Detectors

Electronic gas detectors can check for and record the levels of dangerous gases in the air.

They are often used in commercial and industrial environments where people are exposed to fumes that may harm their health.

The primary function of gas detectors is to sound an alert if the ambient gas concentration rises over a specific safety limit.

Several gas detectors are available and are used for various purposes. The following are examples of popular kinds of gas detectors:

- A single gas detector is used to detect only one gas, such as oxygen, carbon monoxide, hydrogen sulfide, or chlorine.

- The term “multi-gas detector” refers to a gadget that can identify the existence of more than one gas at once. This detector is standard equipment in industrial environments where employees may be exposed to various gases.

- A device permanently put in one place to detect the presence of gases is known as a fixed gas detector. These detectors are often employed in big factories, other industrial settings, and limited areas.

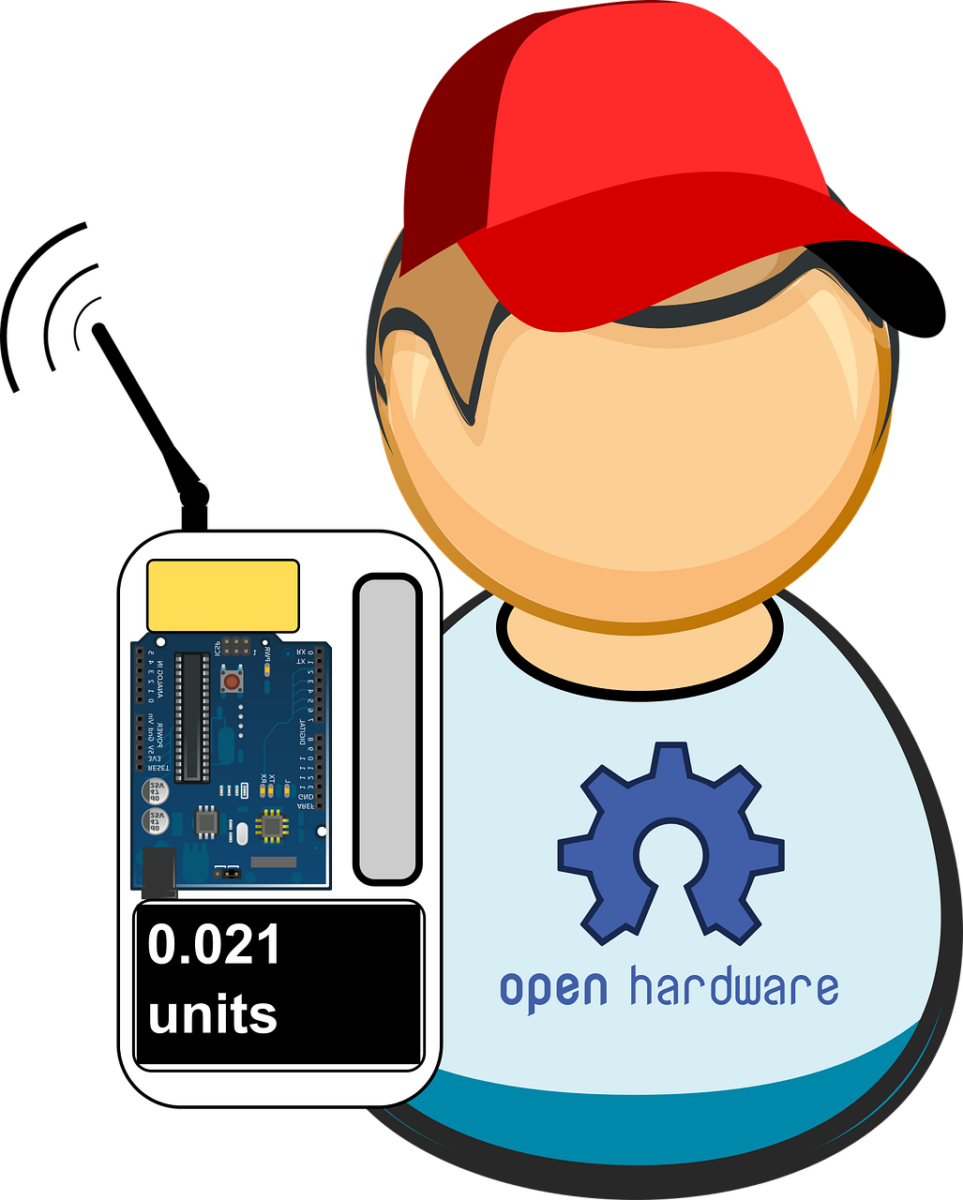

- A portable gas detector is a small, handheld instrument used to detect the presence of gases in an immediate area.

- Electrochemical, infrared, and catalytic sensors are only a few of the methods that gas detectors may use to identify the presence of gases. The gas being detected and the detector’s operating conditions determine the kind of sensor utilized.

Importance Of Gas Detectors In Industrial Settings

It would be impossible to exaggerate the value of gas detectors in the workplace.

The industrial workplace may expose workers to various toxic gases, some of which can be fatal.

Carbon monoxide, hydrogen sulfide, methane, and volatile organic compounds are some of the most often encountered gases in manufacturing and processing facilities.

When dangerous gas levels in the workplace rise over acceptable levels, gas detectors sound an alarm and warn personnel to take cover.

They help reduce the likelihood of accidents and protect people from potentially harmful gases.

Some of the most critical factors that make gas detectors so useful in factories include the following:

When Gas Leaks Are Detected Early On

Employees may take preventative measures before dangerously high amounts of gas are present. This can lessen the chances of gas building up and causing accidents like explosions and fires.

Safety from Dangerous Gases

Breathing difficulties, dizziness, nausea, migraines, and even death may result from exposure to dangerous gases. To protect employees from these dangers, gas detectors alarm when gas levels go too high.

Numerous Sectors

Are subject to safety rules that mandate using gas detectors to protect the safety of employees on the job.

Productivity Boost

Gas detectors assist in eliminating losses in output because of fires, explosions, and other safety emergencies.

When workers feel comfortable and secure in their workplace, they are more likely to work hard and efficiently.

Using gas detectors may save money by minimizing the risk of accidents and the frequency with which expensive repairs and downtime are required. Over time, this might lead to cost savings for enterprises.

Benefits Of Gas Detectors.

Some of how gas detectors can improve workplace safety are as follows:

Gas detectors may avoid mishaps in industrial settings by alerting workers to the presence of toxic gases before they accumulate to lethal concentrations.

The sensors will sound an alarm if the attention of a hazardous gas becomes too high, giving employees time to leave the area or take other measures to avert disasters like explosions and fires.

Using gas detectors in the workplace may significantly increase safety for anyone working with hazardous gases.

Long-term exposure to toxic gases may cause respiratory issues, dizziness, nausea, migraines, and even death among workers.

By notifying employees when gas levels rise over acceptable limits, gas detectors may reduce the likelihood of health concerns.

Gas detectors are a necessary investment for many firms that must adhere to safety regulations.

By assisting companies in meeting the requirements of these rules, gas detectors contribute to the health and safety of employees on the job.

Productivity rises when employees have confidence in their physical and emotional safety.

Having gas detectors in place may help businesses save time and money by preventing injuries and other disruptions to operations.

Businesses that invest in gas detectors may save money by doing so. One may significantly reduce the cost of repairs and downtime if accidents are avoided.

Using sensors, one may lower insurance rates and legal expenses related to accidents caused by hazardous gas exposure.

If a gas leak is detected early on, personnel will have time to fix the problem before toxic amounts of gas build-up.

Gas detectors are user-friendly and need nothing like upkeep or instruction. Calibration and maintenance of most detectors may be performed locally, cutting down on travel time and the requirement for highly trained specialists.

Conclusion

In many fields of work, gas detectors are essential for averting injuries and disasters.

They can identify potentially dangerous gases in the air and sound an alarm, allowing personnel to take preventative measures.

Improved worker safety, compliance with safety requirements, more productivity, and lower costs are just a few advantages of gas detectors.

One may avoid accidents and health problems caused by exposure to dangerous gases, and employees are protected if gas detectors are used and maintained correctly in the workplace.

Manufacturing, mining, refining, and chemical plants are just some of the many settings where gas detectors find widespread usage.

To provide their employees with a healthy and safe working environment, businesses should prioritize gas detectors.