Did you know that around 4,300 manufacturing companies produced core components for the Optics Industry in 2018? Most people associate optical lenses with correcting vision. The truth is that precision optics is much more than that and it spans across various different industries.

Keep reading to learn more about the use of precision optics in completely different markets.

Post Contents

1. Micro Endoscopes

Precision Optics has teamed up to develop camera modules and micro-camera module systems to help in the medical field. This is helping with the advancement in minimally invasive surgeries.

Small endoscopes have been manufactured that are as tiny as .5 mm with illumination. Some of the features of the systems include a corner to corner field of view, a depth field of 3 to 50 mm, and a 0 mm diameter stainless steel sleeve that protects the sensor and lens assembly.

2. Robotic Surgery

Advances in robotic surgery have increased the demand for 3D endoscopes or stereo endoscopes. 2D endoscopy is the standard for handheld applications but with robotic systems, 3D endoscopes are utilized to enhance the surgeon’s perception of the remote surgical field.

When manufacturers are designing 3D endoscopes with two channels it requires for the images to be perfectly matched in color, line of sight, distortion, and magnification. Although the brain is capable of interpreting these images, disparity might end up causing headaches and fatigue. If this is experienced it ends up making the system unusable.

The tolerances for stereo endoscopes have to be much tighter which requires an experienced approach to optics, design forms, features, and mechanics that allow for manufacturability of the tolerances that are required.

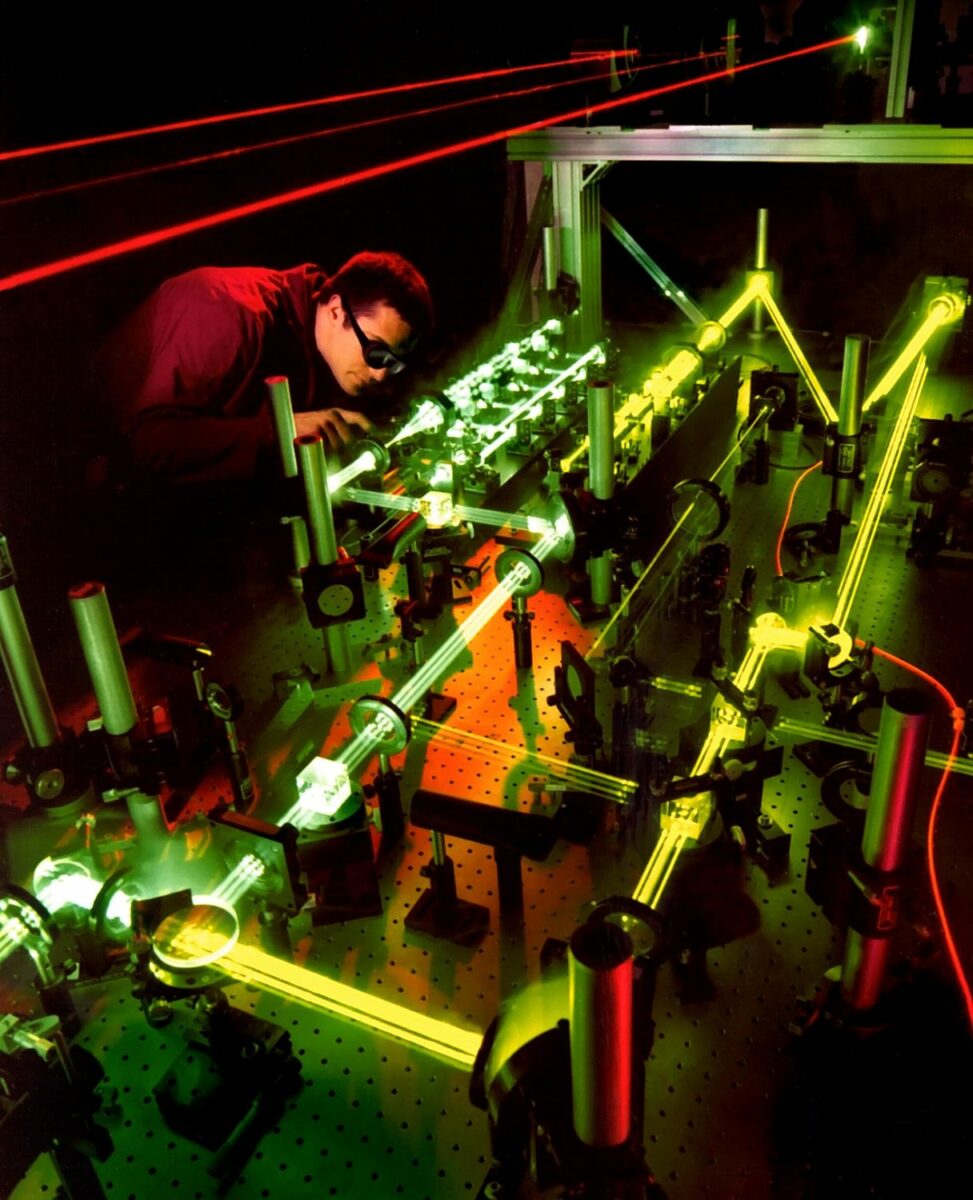

3. Aerospace and Defense

The Department of Defense is always in need of precision optics technology. They relied on a time-sensitive optical system for night vision goggles that were used in the First Gulf War. Precision optics continue innovating in the micro-optics world to make sure they bring in things like illumination for a range of defense applications, along with beam shaping.

In some cases, weight and size are extremely critical in order to have successful missions, and thankfully precision optics engineering can accommodate those challenging requirements. There are tiny microlens systems that are as small as 0.37 mm, Penta prisms, dove prisms, and right-angle prisms as tiny as 0.10 mm.

Precision Optical Lenses Basics

There are plenty of different shapes, materials, and sizes when it comes to precision optical lenses. For every unique customer requirement, there is a lens type available to choose from. The sides can be either flat, concave, convex, or curved.

Each curve might be either steep or shallow. The outer rim does not have to be cylindrical, it can be any shape that fits the package or the function best. The materials can either be a certain glass type, crystals, or plastics.

Precision optical lenses are used with other optics to diverge, focus, or focus light. they can also be used alone.

Sourcing the Material

When fabricating the lenses the first step is choosing the correct material. The factors that go into choosing the best material for the lens is durability, the degree to which it bends light (also known as the refractive index), the cost, and the laser damage threshold.

One of the most popular material choices at the moment is high purity fused silica. The reason that it is so popular is because of how lightweight it is, its range of transparency, and how resistant it is to thermal shock.

To speak to someone live that will answer all of your questions about products and choosing the right materials you can contact someone more than willing to help you right here.

Planning Phase

Once the material is chosen then a plan has to be written out and sent to the shop. The plan has to specify the exact order of operations, the fixtures, methods, target tolerances, and materials to use. Make sure to take details such as quantity to be produced, and the working properties of the lens material into consideration.

The shop will decide which machine is best and also what the best order of operations will be based on your lens needs. For the most part, the following categories are used to group everything:

Blocking

In some cases, multiple lenses can be attached to a backing plate. Then, a single machine operation is able to work between 5 to 100 or even more parts at the same time.

Lapping

Tool marks that are left behind from sharing are removed during lapping. The surface is then made smooth to a satin sheen feel and the final dimensions are done via lapping operations. Sometimes it is done with the same exact machines that are used in rough shaping but with slower feed rates and finer diamonds.

Once lapping is done then the lenses are ready for polish.

Rough-Shaping Lens

When preparing the blanks for finishing operations, the lenses have to be sculpted to approach their final shape and dimensions. The thickness total is machined down and the edges are brought to a final dimension while the curves are scooped out.

This is done with a rotating diamond tool at very high speeds.

Feeling Like a Precision Optics Pro?

We hope that now that you know more about precision optics and the types of precision optics, you are feeling better informed about where you might come across these optics.

Did our article come in handy today? Please keep browsing the rest of this section to make sure you catch our latest tech reads.